Get in touch! +91 79 6952 7575 / [email protected]

Aaag India – Since 1933

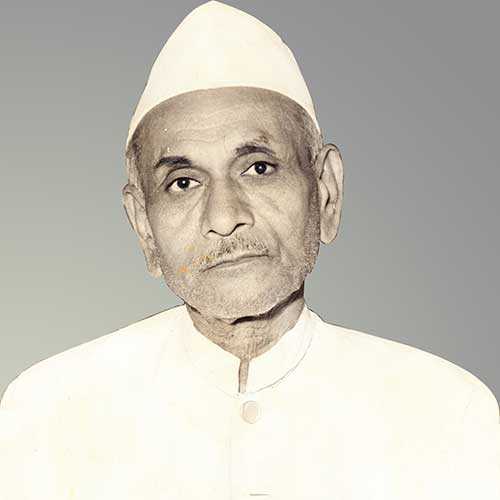

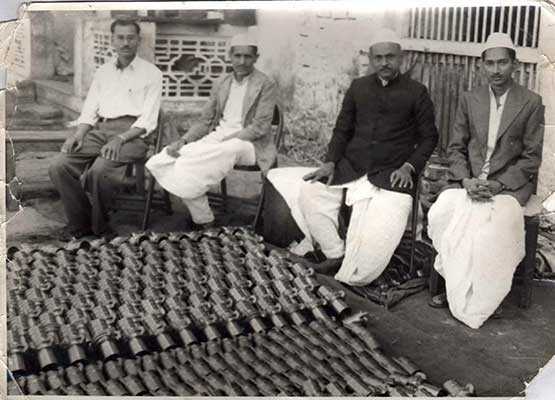

In 1928, the late Shri Bhogilal Jethalal Shah relocated from the small town of Umreth in central Gujarat to the industrial city of Ahmedabad in search of better business prospects. After working at the traditional family business of glass framing for a few years, he set up Shah Bhogilal Jethalal Iron & Brass Factory at Ahmedabad in 1933. The intent was to manufacture brass valves to meet the demand of the burgeoning textile industry, which was then at its peak in Ahmedabad. Over the next decade, however, the textile industry began to decline, and Bhogilal was quick to foresee its negative impact on his business. To counter this problem, he began to manufacture products for different applications and industries, which included supplies to the Defence sector (including Hose couplings to the British army during the Second World War). He zeroed in on Bronze Landing valves, Hose couplings and Nozzles as products with good market potential, and with this launched Shah Bhogilal Jethalal & Bros’s journey on the path of fire protection.

For 2 to 3 decades thereafter, Shah Bhogilal Jethalal & Bros continued to manufacture these products, gaining recognition as a quality producer of fire fighting equipment. On client demand, Bhogilal and successive generations of his family continued to add Various fire-fighting equipments to their product range, and today, the company produces a wide range of water and foam based fire-fighting equipments for fixed, mobile and vehicle based fire fighting applications.

Today, the third and fourth generations of Shri Bhogilal’s family enthusiastically pursue his vision of creating a world class manufacturing organization to meet the world’s fire protection needs. For Bhogilal, quality and reliability of his products were paramount, and after 8 decades, the company’s values remain unchanged, as they continue to manufacture fire fighting equipment whose performance can be relied upon even in the most trying conditions.

Today, AAAG boasts of a modern, 50,000 sq. feet manufacturing facility, with in-house foundry, machining, assembly and testing facilities. The complete range of its products are now manufactured in-house, with state of the art machinery, equipment and fully trained staff. At the same time, the age old traditions of quality and commitment that Bhogilal inculcated in his organization, still remain strongly ingrained in all their activities.